Alrosa has unveiled a new diamond tracking system that uses nanotechnology to engrave gems, potentially allowing them to be traced from the mine all the way to the consumer.

The technology aims to solve the biggest problem in tracking a rough diamond from mine to market: Since rough diamonds are commonly cut, any mark put on the diamond is in danger of being removed.

“The marks currently on the market today are very localized to one part of the diamond,” notes Valentin Konurin, Alrosa’s deputy director of global marketing and head of branding and new projects.

This new technology uses laser radiation to imprint a three-dimensional code inside the diamond’s crystal lattice, which affects the atomic structure of the entire stone.

“So even when it’s polished, you will still have this mark in the body of the diamond,” Konurin says. “You cannot get rid of the mark. Even when it’s manufactured, it stays there.”

He notes that the mark is subatomic, so it has no effect on the stone’s color or clarity and cannot be seen without a proprietary scanner. Each piece of rough will have a unique ID that will let anyone in the pipeline trace the stone back to its mine of origin.

Alrosa is still developing commercial applications for this technology; for now the company is testing it as a business-to-business feature.

“Luxury groups like Kering, Richemont, on the corporate level, they are keen on a guaranteed transparent supply chain,” Konurin says.

But he adds consumers are becoming more interested in diamond origin as well, and Alrosa might develop a consumer-facing aspect—which could let buyers scan their diamonds to learn more information about where the diamond came from and its “story.” For now, however, the technology is better suited for loose stones than mounted ones.

Alrosa plans to patent its technology in the United States, China, and several other jurisdictions. The mark will be applied at Alrosa’s Moscow sorting office and only be used on its Russian-mined goods. The technology won’t work on moissanite and cubic zirconia, which have a different atomic structure than diamonds, but it could work on lab-grown diamonds, as their makeup is the same as that of naturals (though Alrosa doesn’t deal in lab-growns).

Konurin says that Alrosa may still work with other traceability schemes, including De Beers’ Tracr and GIA’s diamond origin reports.

“The more traceability, the better,” he says. “Everyone is trying to do something more than just guarantee origin based on audits and invoices. This has been a very difficult scientific project we have been working on for several years. We have developed our own project, but that doesn’t mean that we won’t join others.”

Is it also possible that, since traceability remains an industry-wide issue, this technology may eventually, say, be used on diamonds tracked by the Kimberley Process?

“We will have to see before we apply it on such a wide scale,” Konurin says.

Alrosa is not the only company looking at nanotechnology as a method of diamond tracking.

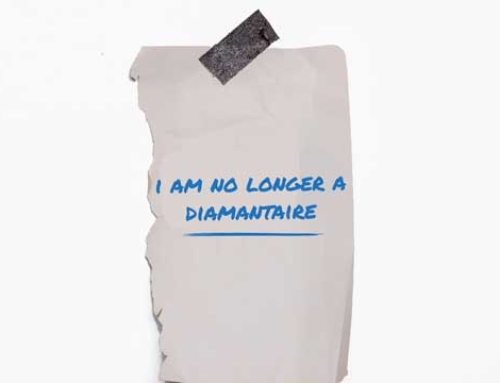

A New York City dealer, Bruno Scarselli, says he’s devised a method, which he is in the process of patenting, that also uses nanotechnology to track diamonds from rough to polished; his version includes a consumer app that tells buyers where their diamonds come from. His company, Nano Innovator, is currently seeking investors.

Opsydia, a U.K. company, also offers a tracking system that uses nanotechnology. Former De Beers executive Jonathan Kendall recently joined Opsydia’s board.

Alrosa developed its new technology with the assistance of scientists from the Russian Academy of Sciences, as well as Alrosa’s Research Geological Enterprise (NIGP) and the Yakutniproalmaz Institute.